CUSTOMER CASE STUDY

Defining Operational Excellence current state and future vision

Many years of accelerated growth through acquisition, with limited opportunity to integrate newly acquired businesses, created a significantly larger organization with new products and capabilities but varying levels of performance and a lack of standard processes and ways of working.

Key Figures

Initially, no standard lead time measured. After Value Stream Mapping exercise, a 40 to 60% reduction from 8 weeks to 2 weeks validated and approved.

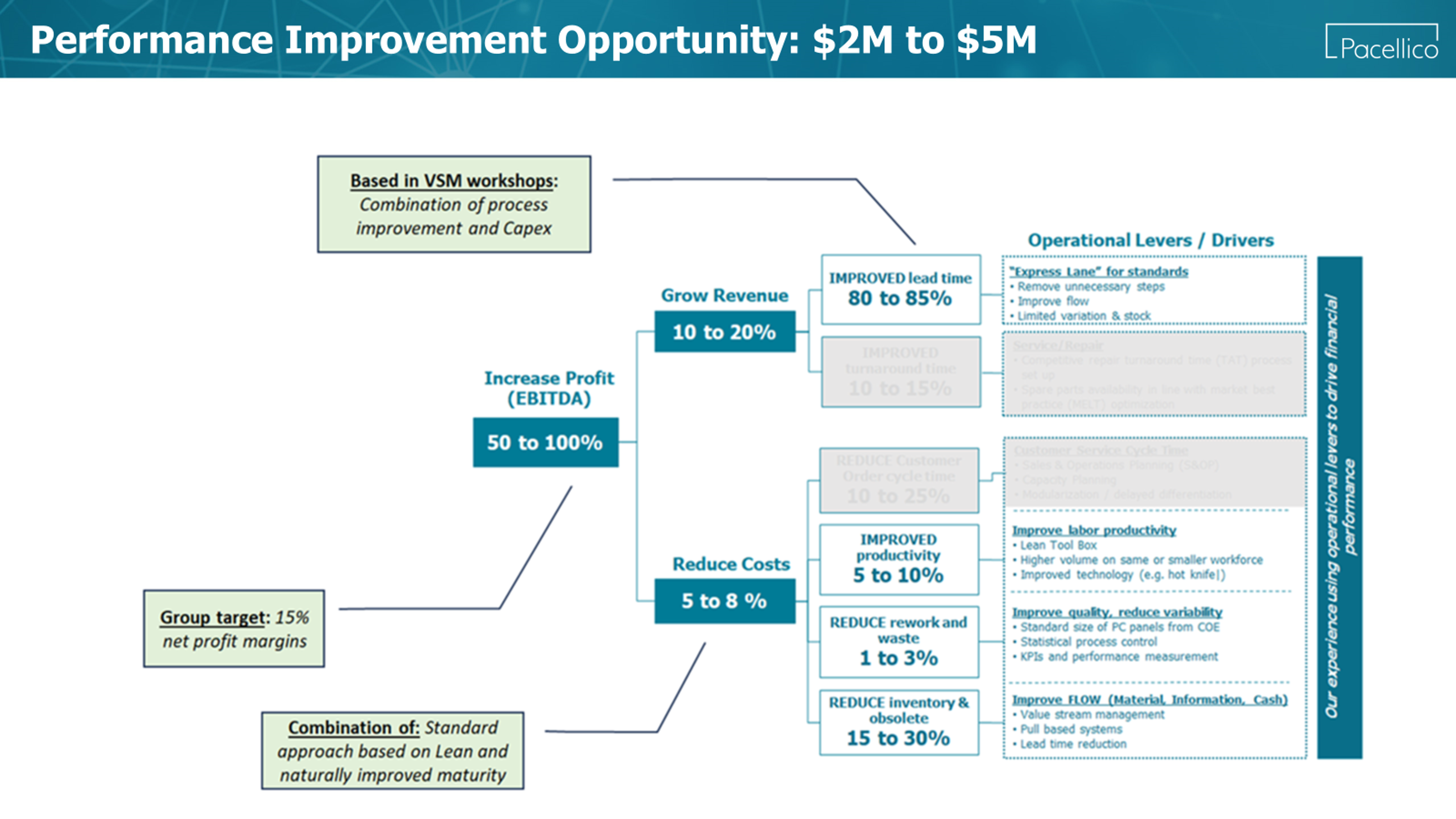

Bottom-up assessment of manufacturing capabilities and costs associated with labor, material, quality, stock and transport validated the Phase 1 saving journey for 18 to 24 months from 8.4 to 10% ROS.

Implementing a new process model with shorter Leadtime and Lean processes will have a significant impact on work-in-process and obsolete inventory.

Approach, Solution and Outcome

A Maturity Assessment Tool was developed and customize based on Operational Excellence best practices. A series of 6 three-day visits was carried out including shop floor observations, brainstorming and action planning workshops.

Additionally, Value stream Mapping sessions were carried out in several factories to assess the opportunity to significantly reduce lead time for standard products.

Together with the cross-divisional Task Force and participants of the individual site visits, a strategy and vison was developed including a set of 10 initiatives to be applied across all sites, individual action plans for each site that was assessed, and an Operations Strategy which includes key metrics and goals, and targeted cost savings to increase profit margins 16% in the short-term and 70% medium-term.

A business case was developed based on bottom-up observations across six sites and joint action place between Pacellico and the client task force

Value stream Mapping with management validated significant opportunities to reduce lead times and reduce costs

Conclusion

Assessing the current state of Operational Excellence across 6 sites and 7 factories in US & Europe generated key insights, a robust business case and a strategy to implement a new system with significant impact on financial performance.

Contact us to schedule a complimentary online free consultation and discuss tailored solutions for your business.

Pacellico Blog

Maximizing Supply Chain Efficiency: 3 Tasks to Outsource and 3 to Keep In-House

AUTHOR Lee Eden Lee has extensive experience in global supply chain, logistics and customer [...]

Embracing Sustainability: A Blueprint for Manufacturing Companies

Sustainability has become a critical focus for businesses worldwide, and the manufacturing sector is no exception. [...]

Navigating Uncertainty: Strategies for Building Resilience in Your Business Operations

No matter which business we are working in, uncertainty is the new normal. While lack [...]