CUSTOMER CASE STUDY

The client faces daunting challenges to build a supply chain capable of delivering multiple SMRs annually at full capacity leveraging a highly standardized, modularized and outsourced supply chain model.

Small Modular Reactors (SMRs) are an innovative alternative to traditional nuclear power plants, featuring the latest technological advancements and enhanced safety measures to provide low-carbon electricity from a relatively small footprint. Designed to be both small and modular, SMRs require a lower initial capital investment and offer greater scalability. They can be sited in locations unsuitable for larger nuclear plants, providing flexibility in choosing suitable sites. These reactors complement existing power plants and can help decarbonize various sectors such as transport, chemical industries, and district heating.

SMRs are a promising solution for achieving net-zero emissions by delivering clean, flexible, and efficient nuclear energy options.

Key Figures

Story

The advent of SMR technology is a significant opportunity, globally, for meeting net zero emission targets safely, effectively and at scale. To do so and meet economically viable LCOE* targets requires a modular strategy where many suppliers are managed in a modular format where cost, quality and delivery attributes are significantly higher level than traditional nuclear build, with the same or improved safety standards and performance.

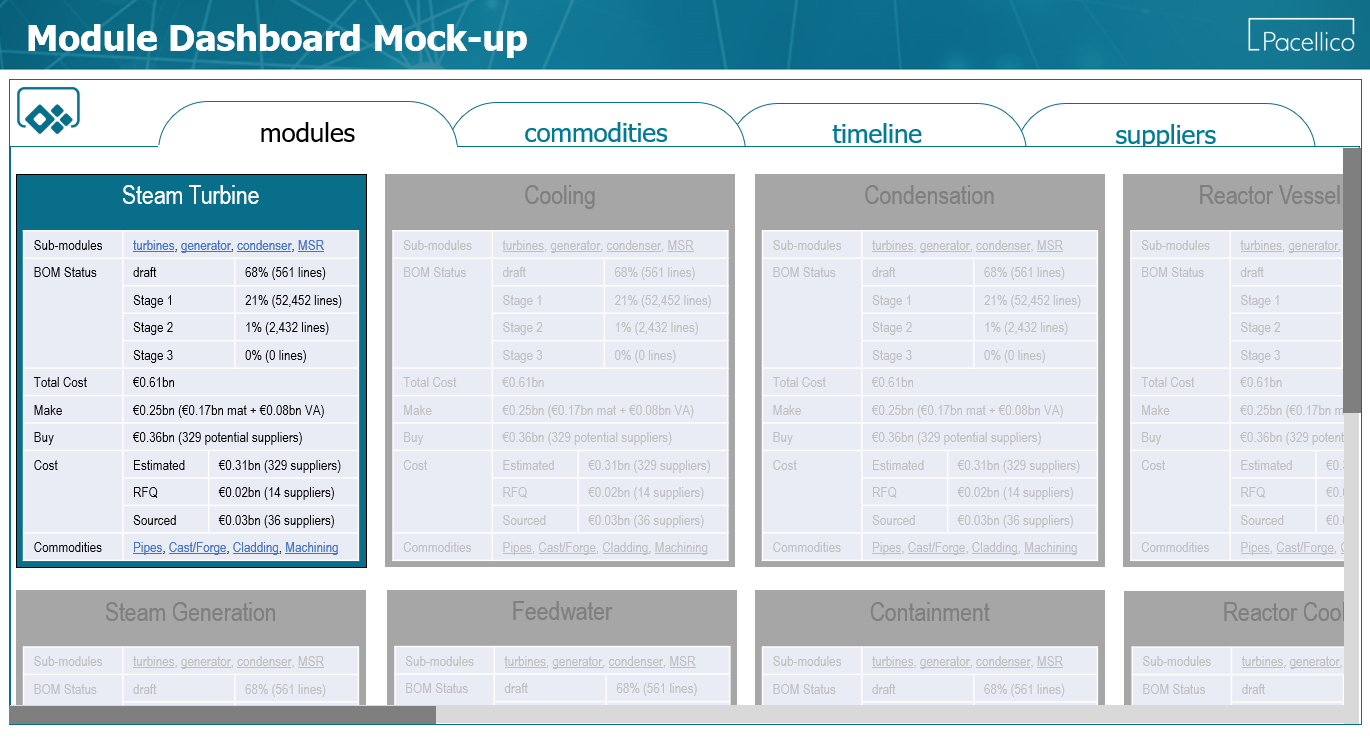

To facilitate these outcomes, we supported our client with a four phase Supply Chain development project where we 1) mapped and visualized the SMR supply chain modules 2) supported the Make vs. Buy analysis of each module 3) developed a digital supply chain management concept to ensure a “common view” of the products for all functions including supply chain management and 4) facilitated the maturity assessment and development of the supply chain organization to meet the needs of current and future SMR delivery program.

*LCOE = levelized cost of electricity

A series of Supply Chain mapping workshops enabled our client to define the optimal critical path for ramping up the supply base quickly.

Multiple systems and “views” of the supply chain – including financial, engineering, technology focused, etc. – required a “one source of truth” approach.

Conclusion

SMR proliferation is expected to be a leading component of any sustainable energy mix in the very near future, SMR manufacturers are ramping up for first of fleet in the middle part of this decade.

Manufactures face huge supply chain challenges and constraints. Our supply chain visualization project facilitated the mapping, and prioritization of key suppliers in US, Asia, Western and Eastern Europe – the key markets where SMRs are expected to break ground shortly.

Contact us to schedule a complimentary online free consultation and discuss tailored solutions for your business.

Pacellico Blog

Embracing Sustainability: A Blueprint for Manufacturing Companies

Sustainability has become a critical focus for businesses worldwide, and the manufacturing sector is no exception. [...]

Navigating Uncertainty: Strategies for Building Resilience in Your Business Operations

No matter which business we are working in, uncertainty is the new normal. While lack [...]

The Synergy between Leadership and Management for Business Growth

In today's rapidly changing business landscape, organizations must be agile, innovative, and growth-oriented to survive [...]